|

We can propose a low-cost and high-quality on-site construction plan that organically combines on-site assembly operations with large heavy machinery, etc. We measure the 3D displacement and strain of the steel members being assembled in real time and carry out on-site construction operations under stringent safety control, all while providing adequate care to the soundness of the structures. When the assembly of blocks is performed on the ground, for such purposes as reducing elevated operations, it is referred to as “ground assembly.” Ground assembly is used when it can provide benefits in consideration of the size, member structure, and number of members, etc. We smoothly execute ground assembly by reviewing in detail the shape and quantity of ground assembly bases and ground assembly space, etc. |

|

|

There are two cases involved in this regard: When tensile strength is applied by the self-weighting of the structure body or when it is applied forcibly. Several methods are available to apply tensile strength by force. An appropriate method is selected according to the member size and tensile-strength level. There are several methods to control the applied tensile strength, such as individual control and centralized control, etc. We select an optimum control method according to the conditions present, according to need for tensile-strength control accuracy or the number of the members. |

|

This is a construction method that divides a large roof unit into multiple blocks, then moving the blocks using a construction crane. This method is used when the overall rigidity of the framework is low or when ground assembly space is available outside. We achieve highly safe construction by reviewing and planning the selection of the crane, suspension device plans, support pillar layouts, and the timings and methods of support pillar removal, etc. |

|

|

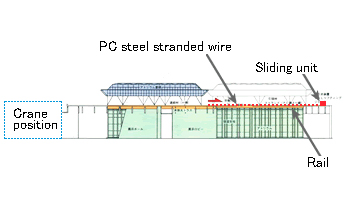

This is a construction method that assembles structure blocks on a base and then moves the structure horizontally using a winch, etc. This method is used when a construction crane cannot cover the entire framework or when there is insufficient room at the site. A rectangular shape is desirable for a roof framework. We achieve smooth construction by reducing friction resistance by using temporary rails and by making plans according to the rigidity, strength, and shape of the structure body. |

|

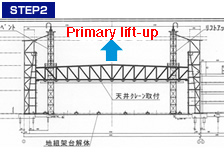

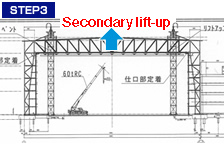

This construction method lifts up a large roof assembled on the ground using a pre-built main pillar (or a temporary pillar) as a reaction force. This method is used when the height for the construction cranes is limited or if elevated operations need to be reduced. We achieve smooth construction by preparing a construction plan that prevents lateral vibration during construction and that ensures the safe use of jacks. |

|

|

|

This is a construction method that provides hinges with a large-span structure in advance and, using temporary pillars, pushes the structure up to the final height after ground assembly. This method is used when the camber of the roof is large and when the roof is symmetric on a plane, or when there is no space for ground assembly outside. We simulate the changes of shape during construction, review the construction method of the closing parts (including scaffolding), make plans suitable for the change of push-up load or imbalanced displacement, and achieve highly safe construction. |

|

|

|

|