|

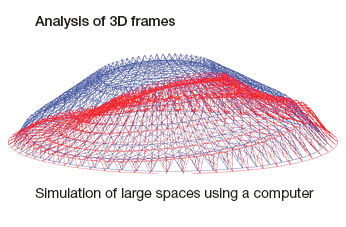

We maximize our performance by combining the latest technologies related to steel materials and analyses, including large-scale 3D structural analysis, the geometrical non-linear analysis of tension structures, dynamic non-linear analysis for high-rise buildings, the FEM analysis of joints using cast steel or extremely thick members, and analysis performed during construction in which complex erection processes are simulated—along with know-how supported by our many achievements involving the construction of steel structures. |

||

|

By comparing the advantages and disadvantages of the structure’s performance, construction properties, and cost, etc., from various framework types, we can propose an optimum solution during the design stage. In the design of large-span structures, it may be necessary to perform large deformation analysis, buckling analysis, or dynamic analysis, in addition to simple static stress analysis. These various analysis results are appropriately implemented into design. |

||

|

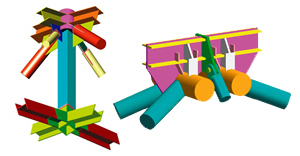

In the design of a steel frame structure, it is important to design the joints of the members. In particular, at the joints of a large-span structure, it is difficult to make designs using what are called “standard details.” For this reason, joint details with appropriate rigidity, strength, and good construction properties are individually designed. For complex joints, design validity is checked by FEM analysis. | ||

|

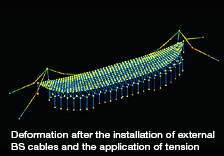

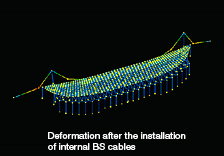

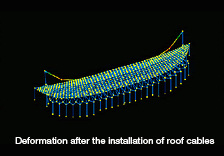

In a large-scale structure, any error in procedures may ruin the stress or deformation estimated in the structural design process. Construction analysis is performed along with the construction procedure before the actual construction, and the stress/deformation state at the completion of the building is studied before coming up with an appropriate construction plan. |

|